250 Um Or Less Using A Ball Mill Eg S石灰石x Industries 8000

Effect of ball and feed particle size distribution on the milling

2018年6月1日 In this article the effect of grinding media size distribution and feed material particle size distribution (PSD) on the product fineness requirements were investigated A 2023年10月27日 Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the A Review of the Grinding Media in Ball Mills for Mineral 2017年9月1日 The use of this shape classification system clarifies that the lessrounded distribution for the ball mill ultrafine sample is due to the particles being more elongated rather Fine grinding: How mill type affects particle shape characteristics Abstract: The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Basic kinetic and energy models of Grinding in Ball Mills: Modeling and Process Control

A comparative study on a newly designed ball mill and the

2020年1月1日 The discharge end design of a ball mill plays an important role in discharging the desired particle sizes (−150 + 10 µm) and the percentage of recirculating load from the 2021年2月19日 The optimum process parameters setting concluded that balls to powder weight ratio are 20:1, the optimum ball mill working capacity is 2 L while the optimum speed of the ball Comparative Study on Improving the Ball Mill Process 4 天之前 Figure 1 shows the grinding power required to grind a sample of KCGM pyrite concentrate to different target P80 grind sizes, using a ball mill (with 9mm steel media) or an Fine Grinding as Enabling Technology – The IsaMillA series of wet grinding experiments have been carried out using a stirred ball mill to systematically investigate the effect of processing conditions on the final particle size Ultrafine grinding of inorganic powders by stirred ball mill:

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Basic kinetic and energy 2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and (PDF) EnergyEfficient Advanced Ultrafine Planetary ball mills are ideal for nanoscale grinding and mixing Vibratory Ball Mills: Utilizing vibrations, these mills are suitable for ultrafine grinding and mixing of materials Vibratory ball mills provide highenergy input to the grinding media, resulting in Ball Mill Grinding Machines: Working Principle, Types, Parts Ball mill adalah peralatan yang umum digunakan dalam proses pembuatan bubuk, seperti bubuk mineral, bubuk logam, dan bubuk batu keramik Ball mill terdiri dari silinder yang berputar secara horizontal, yang diisi dengan media Ball Mill: Fungsi, Cara Kerja, Jenis Dan

.jpg)

(PDF) Effects of Ball Size Distribution and Mill Speed and

2020年7月2日 In recent research done by AmanNejad and Barani [93] using DEM to investigate the effect of ball size distribution on ball milling, charging the mill speed with 40% small balls and 60% big balls 2022年3月15日 These mills consume enormous amounts of electrical energy (5060%); consequently, comminution costs roughly 60% of the overall investment in a beneficiation plant [2,3]Power consumption management and simulation of 2024年7月12日 A ball mill and a tumbling mill are both types of grinding mills used to reduce material size We mainly use a ball mill for mixing and grinding processes In contrast, we generally use a tumbling mill for finer material reduction What are the balls? Ball mills grind materials into an extremely fine formWhat Is a Ball Mill and How Does It Work? (Overview 2024)2015年4月24日 2 Ball mill consist of a hollow cylindrical shell rotating about its axis Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the shell is lined with abrasion resistant materials such as Manganese,Steel or rubber Length of the mill is approximately equal to its diameter Ball mill PPT Free Download SlideShare

.jpg)

Understanding fine ore breakage in a laboratory scale ball mill using

Dimensions Size Unit Internal diameter Internal length Axial slice length Lifters Six square Corner radius Mill speed 435 457 825 mm mm mm 8 1 41 64 mm mm rpm % critical 27 ± 05 1267 805 24 78 157 mm kg g % Ball charge Ball size (Nominal 1 in) Mass of media (in slice) Mass/ball Ball charge (by volume) Media sg Number of malls (in slice 2014年3月1日 The multisegment ball mill model developed by Whiten and Kavetsky has been used together with an extensive range of data from operating mills to establish the parameters of a new ball mill model (PDF) Analysis of ball mill grinding operation using mill power 2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Calculate and Select Ball Mill Ball Size for Optimum Grinding2018年2月1日 In another study to investigate ball size distribution on ball mill efficiency by Hlabangana et al [50] using the attainable region technique on a silica ore by dry milling, a threeball mix of Effect of ball and feed particle size distribution

Redox catalysis in a ball mill,Science XMOL

2019年12月19日 Redox catalysis in a ball mill Science ( IF 447) Pub Date : , DOI: 101126/science36664721467c Jake Yeston Mechanochemistry Mixing solid reactants in a ball mill is a promising means of avoiding the copious solvent waste associated with Types of Ball Mills Vibratory ball mills: These mills use vibration to grind materials, and they are often used for highcapacity applications such as milling ores or minerals rod mill and AG/SAG mill for grinding in a variety of industries and materials Contact : info@ballmillssupplier; Tel: +86 ; Add: 19F, Suite B A Comprehensive Guide to Finding the Best Ball Mill for Sale2012年12月15日 Ball milling is a method of production of nano materials This process is used in producing metallic and ceramic nano materials These mills are equipped with grinding media composed of wolfram carbide or steel Ball mills rotate around a horizontal axis ,partially filled with the material to be ground plus the grinding mediumNano Ball Milling PPT Free Download SlideShare2020年3月1日 SEM photograph (Â200), unmilled Al without CNTs for rotation speeds of (ab) 100 and (cd) 150 rpm at different milling times of 5 and 15 min(PDF) Al/CNT nanocomposite fabrication on different

Understanding the SAG Mill in Copper Ore Mining Process

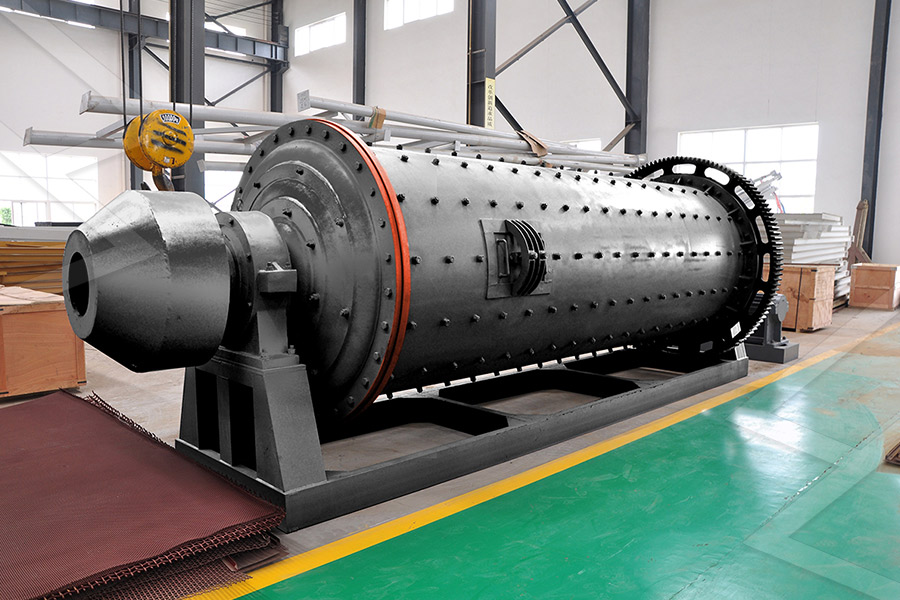

2023年10月10日 The ball mill is one of the most commonly used grinding machines in various industries It works by rotating a cylinder filled with balls, which crush and grind materials into fine powders This machine is known for its high efficiency and versatility in processing different materials They are also more energyefficient than ball mills 2023年6月27日 Nevertheless, parameter factors, such as the type of ball milling, balltopowder ratio (BPR), rotation speed, grinding period, size and shape of the milling media, and process control agent (PCA (PDF) Producing Metal Powder from Machining Chips Using Ball 2024年1月28日 2 Liners: An abrasionresistant material such as manganese steel or rubber typically lines the inner surface of the cylindrical shell to protect it from wear due to the grinding action 3 Balls: They place steel or ceramic balls, typically used as grinding media in a ball mill, inside the shell and rotate them with it 4 Feed and Discharge: Entering the hollow shell at the Ball mill: Principles, construction, working, uses, merits, and Whereas 30 years ago the rule of thumb for designing AG/SAGBall mill circuits was to split the total installed motor capacity 50:50 between the AG/SAG and ball mill circuits, Tozlu and Fresko's Definition of Mill Diameter D, Mill Length L, and Effective

.jpg)

What is a Ball Mill Explained: InDepth Guide JXSC

2024年4月28日 Critical Speed: Critical speed is the hypothetical speed at which the centrifugal force is equal to the gravitational force, and the grinding media starts sticking to the inner shell of the equipment instead of falling freelyGrinding at or close to critical speed of the mill yields a poorer grinding efficiency The ball mills are mostly operated at 6575% of the critical speed to At Fox Industries, we pride ourselves on providing premium ball mill media that meets industry standards Here’s why we stand out as the best choice: Expert Guidance : We have a team of industry experts ready to help you select the Ball Mill Media FOX Industries2020年2月1日 Nowadays, ball mills are used widely in cement plants to grind clinker and gypsum to produce cement In this work, the energy and exergy analyses of a cement ball mill (CBM) were performed and Energy and exergy analyses for a cement ball mill of a new 2024年1月26日 Coarse grinding is done in first chamber and the maximum size, which comes in second chamber, is less than 8 mm Fine grinding is done in second chamber of ball mill Air is sucked through the mill, which takes out the fine ground cement from the ball mill Bucket elevator takes the fine ground powder from the ball mill to the putation of charging media for a double compartment cement ball mill

.jpg)

Effect of ball and feed particle size distribution on the milling

2018年6月1日 A number of researchers (Deniz, 2012; Bwalya et al, 2014; Petrakis et al, 2016) carried out studies about the effect of feed particle size and grinding media size on the grinding kinetics of different oresKhumalo et al, 2006 postulated that generally larger sized grinding media would break larger particles quicker but a finer product would be obtained by use of 2017年7月3日 The voids (or interstitial space) within a rod load are approximately half those in a ball mill grinding load Rods in place weigh approximately 400 pounds per cu ft and balls in place approximately 300 pounds per cu ft Thus, quantitatively, less material can progress through the voids in the rod mill grinding media than in the ball Ball Mills vs Rod Mills 911MetallurgistA: If a ball mill uses little or no water during grinding, it is a 'dry' mill If a ball mill uses water during grinding, it is a 'wet' mill A typical ball mill will have a drum length that is 1 or 15 times the drum diameter Ball mills with a drum length to diameter ratio greater than China Ball Mill Manufacturers Suppliers Factory Customized Ball Mill 2024年8月8日 Choosing the right grinding media for ball milling involves a strategic assessment to align with operational goals, material characteristics, and cost constraints Here’s a stepbystep guide to facilitate this critical decisionmaking process: Step 1 Assessing Milling Requirements: The first step is a thorough analysis of the material to be Ball Mill Success: A StepbyStep Guide to Choosing the

05 TO 15 TPH SMALL SCALE MINER’S BALL MILL

Standard mills are furnished with liners to avoid replacement of the shell; however, the mill can be obtained less liners This ball mill is often driven by belts placed around the center, although gear drive units with cast gears can be furnished A Spiral Screen can be attached to the discharge Ball Mill Capacity Table SMALL BATCH BALL MILL2024年8月8日 A planetary ball mailing machine was used to degrade methylene blue (MB) dye aqueous solution through the SrBi4Ti4O15 (SBT) catalyst The catalyst was synthesized by a solidstate reaction route and characterized by Xray diffraction, Scanning electron microscopy, Xray photoelectron spectroscopy, and Raman spectroscopy The SBT catalyst degraded 65% of Ball millinduced dye degradation using SrBi4Ti4O15 catalyst 2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of Ball Mill Design/Power Calculation 911Metallurgist2024年6月21日 An important decision criterion for using a ball mill as the principal size reduction machine is its enormous flexibility in the ultrafine range With the SuperOrion ball mill, fine products such as paper Motor kW 200 250 315 355 450 500 630 710 900 1120 Throughput t/h of zircon sand d 50 1 µm Classifier ATP 04 315/3 06 315/6 07 315/6 HOSOKAWA ALPINE Aktiengesellschaft SuPER

Nova S Ball Mill Bühler Group

The unique design of the grinding chamber allows energyefficient grinding with up to 30% less energy consumption This can lead to annual energy saving amounting up to €45000 Nova S ball mill is the preferred solution for fine 2022年10月1日 Based on the standard procedure defined by Bond, the ball mill work index is determined by simulating a closed cycle dry grinding in a laboratory Bond ball mill until a stable circulating load of 250% is established (Bond, 1949, Bond, 1952, Bond, 1961) The ball mill work index is determined by Eq (10) The recommendation is the ball mill A new methodology to obtain a corrected Bond ball mill 2018年6月20日 This document describes an experiment to demonstrate a ball mill operation at different speeds and a sieve shaker operation Coarse stone samples were ground in a ball mill at 20%, 40%, and 60% motor speed for 15 minutes then screened More stone was ground to 250600μm size at higher speed, with 013g, 017g, and 024g for 20%, 40%, and 60% Exp 4 Size Reduction Using Ball Mill PDF Metalworking 2017年9月1日 The first stirred mill was installed in the platinum industry in 2002, and by the year 2010, forty stirred mills had been installed at various platinum operations in South Africa, and these led to a step change in flotation recoveries (Rule, 2011, Rule, 2010)Over the last decade, approximately 200 Automated Scanning Electron Microscopy (AutoSEMEDS) systems have Fine grinding: How mill type affects particle shape characteristics

Using a Ball Mill for Black Powder Production: How It Works

2023年8月17日 Using a ball mill to make mixed black powder is a specific operation, but safety is crucial Place the media and any other materials in a container When the container is filled, it is linked to the rolling platform, and the milling process beginsBall Mills Steel Ball Mills Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s The basic construction of a ball mill is a cylindrical container with journals at its axisOrbis Machinery Ball Mills Ball Mill Drive行星式球磨仪PM00强劲的电机,研磨时间短效率高,快速将样品研磨至微米及纳米级,还是适用于胶体研磨及机械合金制备。研磨催化剂, 化学品, 合金, 头发, 木炭, 植物原料, 水泥熔渣, 涂料和油漆, 混凝土, 混合肥料, 焦炭行星式球磨仪PM100德国RETSCH(莱驰)研磨仪粉碎仪2024年4月14日 The choice of milling media is not arbitrary The size of the grinding balls influences the final particle size; smaller balls are better for achieving a finer product Similarly, the material of the balls affects their impact strength and durability, with metal balls being preferable for harder and denser materials while plastic balls may be the perfect choice for some lower Particle Size Reduction Milling Media Economy Ball Mill