Bauxite Grinding And Crushing For Aluminum Process

Physical Bauxite Processing: Crushing and Grinding of Bauxite

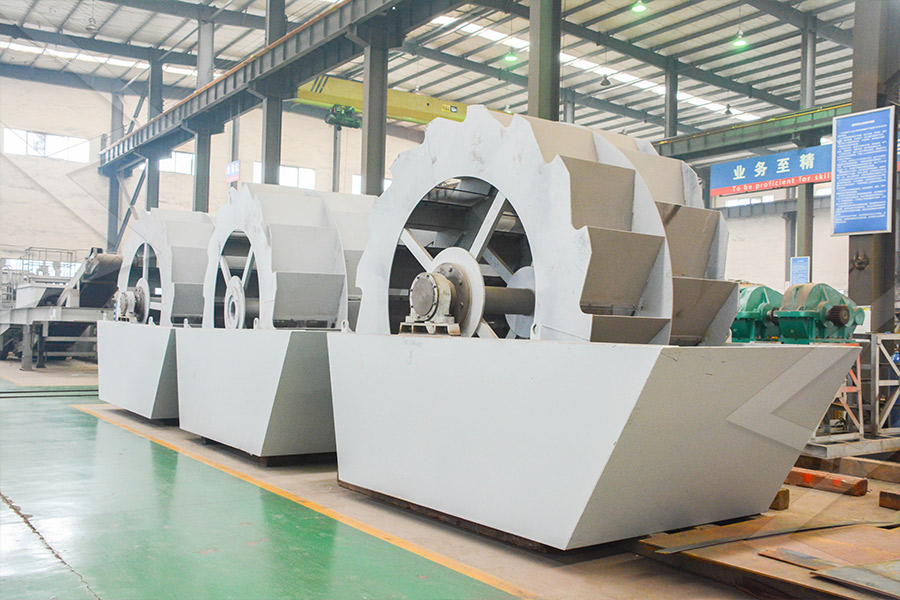

2022年1月23日 The most common initial process step to feed an alumina refinery with bauxite is the crushing or sizing of the raw bauxite material that is extracted from the mine The feed material is crushed or sized so that it is conveyable, as well as correctly dimensioned, for the 2022年1月23日 The most common initial process step to feed an alumina refinery with bauxite is the crushing or sizing of the raw bauxite material that is extracted from the mine The feed Physical Bauxite Processing: Crushing and Grinding of 2022年1月23日 The Bayer process is a chemical process for refining aluminium hydroxide, Al(OH) 3 from bauxite; this aluminium hydroxide is subsequently calcined to produce alumina, (PDF) Chemical Processing of Bauxite: Alumina and Silica This book provides a comprehensive review of the production of smelter grade alumina from bauxite ores It emphasizes the best practices applied in the industry today but seen in a historical context with a view to future challenges Smelter Grade Alumina from Bauxite: History,

.jpg)

Physical Bauxite Processing: Crushing and Grinding of Bauxite

2022年1月23日 The most common process step to feed an alumina refinery with bauxite is sizing of the raw bauxite material that is extracted from the mine The first crushing of the A concentrate with A/S over 7~12 can be obtained by the new process of elective crashing and grinding from bauxite with middlelow grade The advantages of the new process are simple Selective Crushing and Grinding to Process Bauxite with 2023年11月1日 One of the most promising options to circumvent that problem is alumina recovery before smelting to remove iron The main focus of this paper is to give a comparative Alumina recovery from bauxite residue: A concise review2022年3月12日 In the production of aluminium from bauxite, the intermediate alumina (Al 2 O 3) is produced by a combination process; the alumina is subsequently smelted to aluminium via a THE ALUMINIUM STORY BAUXITE TO ALUMINA: THE

.jpg)

Introduction: Primary Aluminum–Alumina–Bauxite

2022年1月23日 This book centers on the production of purified alumina (Al2O3) that is used as a feedstock to smelting cells that convert alumina to purified aluminum (Al) The smelting 2022年1月1日 AbstractThe most common process step to feed an alumina refinery with bauxite is sizing of the raw bauxite material that is extracted from the mine The first crushing of the Physical Bauxite Processing: Crushing and Grinding of Bauxite2022年1月1日 Read the article Physical Bauxite Processing: Crushing and Grinding of Bauxite on R Discovery, your goto avenue for effective literature search AbstractThe most common process step to feed an alumina refinery with bauxite is sizing of the raw bauxite material that is extracted from the mine The first crushing of the bauxite may often take Physical Bauxite Processing: Crushing and Grinding of Bauxite2020年3月31日 This laboratory study investigates selective grinding and beneficiation options for a Greek bauxite ore First, a series of batch grinding tests were carried out in order to investigate the Grinding Behavior and Potential Beneficiation Options of Bauxite

Introduction: What is Bauxite and What is the

2023年3月20日 Bauxite ore separation methods generally use flotation, using a twostage flotation process as follows Firstly crushing and fine grinding of the raw bauxite ore to 95% passing a 200 mesh sieve Separation or enrichment of 2022年3月12日 In the production of aluminium from bauxite, the intermediate alumina (Al 2 O 3) is produced by a combination process; the alumina is subsequently smelted to aluminium via a pyrometallurgical process If bauxite is treated hydrometallurgically with an acidic solution (say hydrochloric acid), notTHE ALUMINIUM STORY BAUXITE TO ALUMINA: THE 2020年12月21日 Bauxite can be found in a number of different physical forms including: pisolitic, friable and hardcap Each bauxite will have its own distinctive crushing and milling characteristics Bauxite can be highly variable through the mine pit profile, both vertically and horizontally Often large blocks from blasted or ripped bauxite can be upto 1±2 m 3AA04 Bauxite Particle Size Requirements for the Bayer 2023年2月15日 Underground the above processes washing, crushing, grinding, the bauxite particles are reduced to increase the available surface area for the digestion stage Step 4 Digestion process In the digestion process, the slurry is heated to 270℃ to form a sodium aluminate supersaturated solution or "pregnant liquor"How to Get Aluminum from Bauxite Reduction Process

.jpg)

Bayer Process an overview ScienceDirect Topics

The Bayer process is the most commonly used refinement route, though certain countries use alternatives called the combined or parallel BayerSinter process and the Nephelinebased process [20, 37]This section describes purely the Bayer Process Due to the impurities in the bauxite ore, it requires treatment to produce purer alumina, Al 2 O 3 [18]This is achieved by 2023年4月1日 The spent sodium aluminate solution was recycled via an evaporating procedure to dissolve more alumina in the digestion process The aluminum hydroxide was washed and then calcined to form alumina The main aims of this work are to review existing literature on gibbsitic bauxite process discharge reduction and expected technologies for red Toward sustainable green alumina production: A critical 2021年9月5日 Bauxite is a rock type that is used to produce metallurgicalgrade alumina and chemicalgrade alumina/aluminum hydroxide using the Bayer process During this process, the finely ground bauxite ore is digested under pressure in a strong caustic (sodium hydroxide) solution at temperatures ranging from 100 to 260 °CModeling of Bauxite Ore Wet Milling for the Improvement of Process 2019年2月5日 High pressure grinding roll (“HPGR”) technology is very rapidly gaining a wide acceptance within the mineral processing industry Benefits, including a superior energy efficiency and a lower HPGR Grinding Technology and its Application to the Bauxite

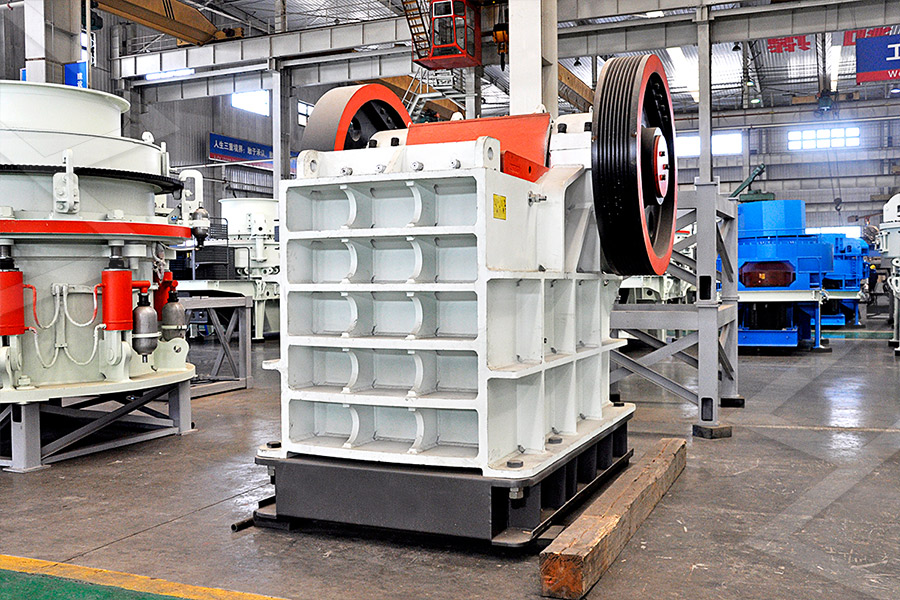

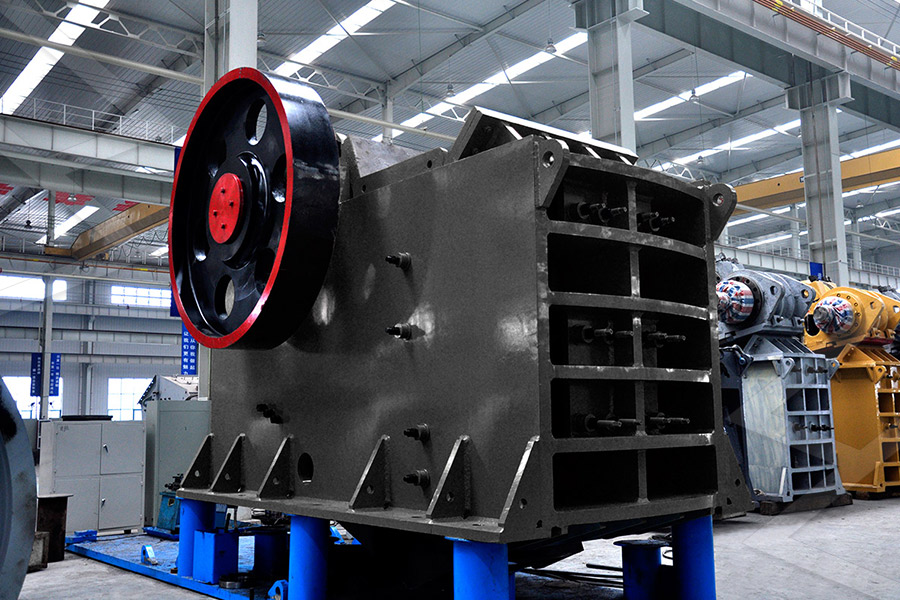

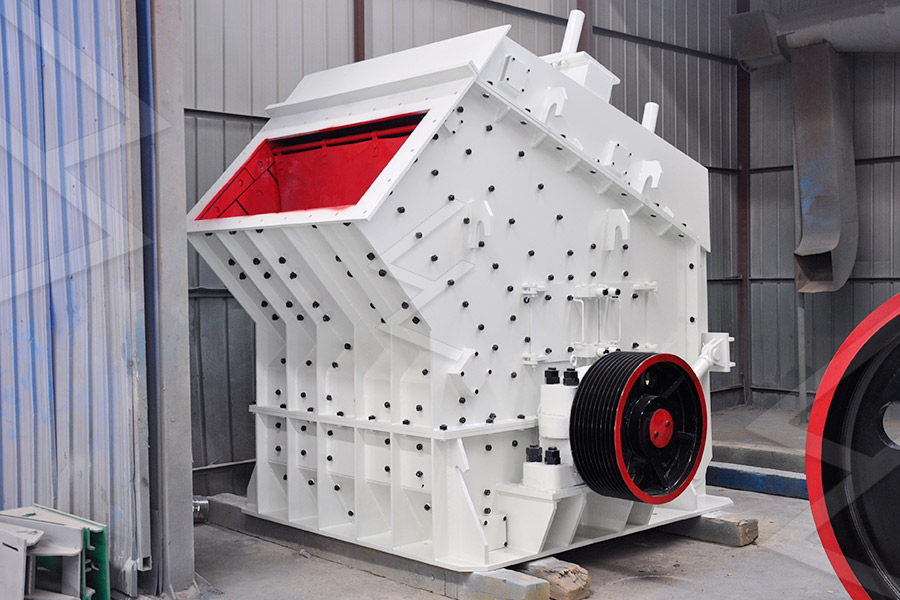

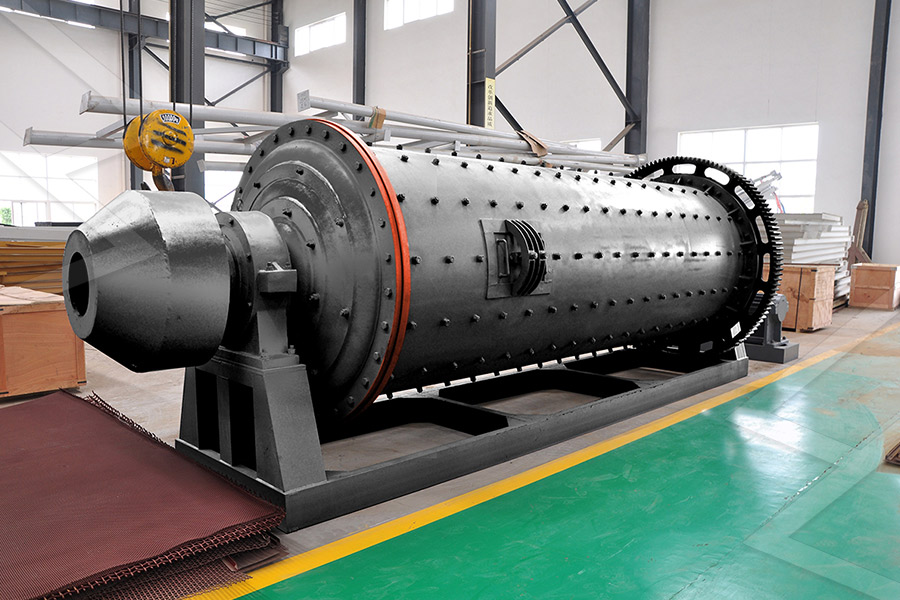

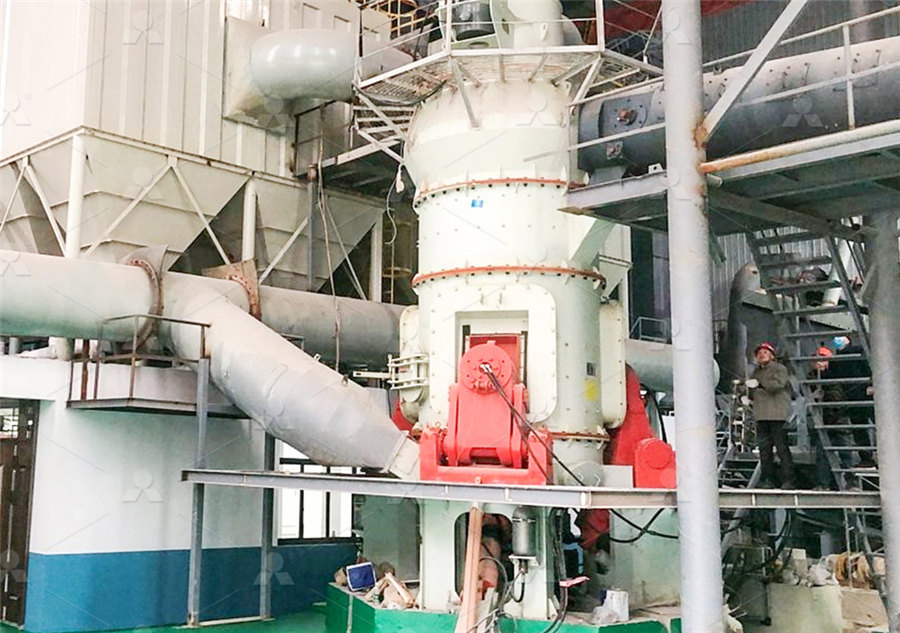

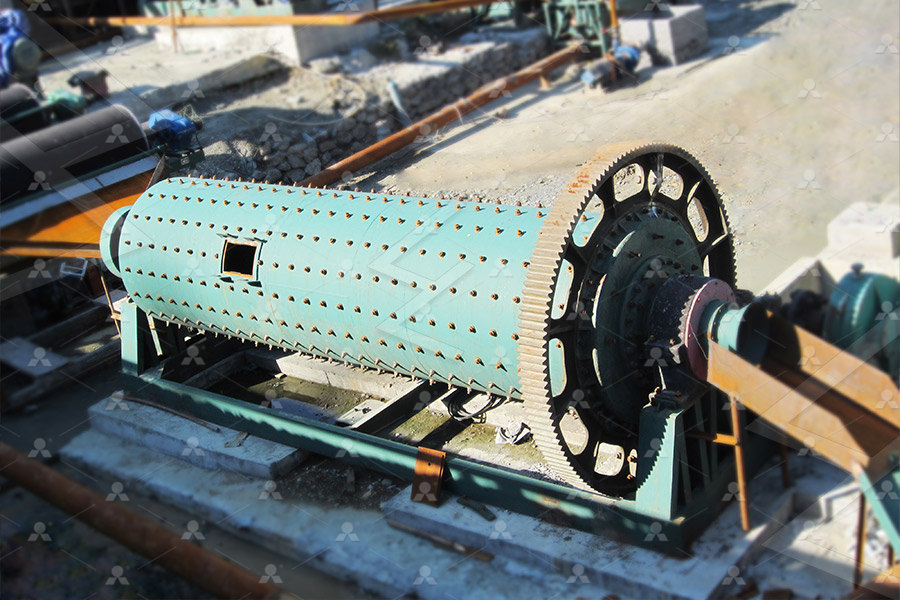

Crusher and milling machine application in bauxite processing

The purpose of this machine is to grind materials into powder form for further processing The milling process involves three steps: crushing, grinding and classifying Firstly, the bauxite ore is crushed into small particles by crusher machines Then, these crushed particles are fed into the milling machine where they are ground down even furtherThese machines work together to process bauxite into a fine powder suitable for various industrial applications such as aluminum production, ceramics, and refractories Introduction of Bauxite powder ite powder is a kind of fine powdery material obtained by crushing and grinding bauxite Bauxite is the main raw material for refining aluminum Which machines are needed to process bauxite powder?2024年10月25日 Bauxite flotation process plant 1 The mined bauxite mixture is screened through a singlelayer or multilayer screen surface by a vibrating screen; 2 Preliminary crushing of the screened aluminum ore by the jaw Bauxite Beneficiation Tailings Reprocessing 2022年1月23日 The Bayer Process was patented in 1888 in Germany by the Austrian chemist, Karl Joseph Bayer []The simple chemistry of the process is that the hydrated forms of aluminum in bauxite, readily dissolve in heated caustic (NaOH) solutions (the DIGESTION step, see Chap 4)The advantage is that nearly all of the minerals in bauxite containing other metallic ions do Introduction: Primary Aluminum–Alumina–Bauxite

.jpg)

The industrial alumina production processes in Europe and

2020年12月15日 The Bayer process produces pure aluminium hydroxide from bauxite As shown in the figure below, this process utilises the different thermodynamic properties of the caustic soda – aluminium hydroxide system and typically consists of the following stages: bauxite crushing grinding, leaching, physical separation, precipitation and 2023年4月3日 The process of extracting aluminum from bauxite involves crushing and refining the mineral to produce alumina, which is then used to produce aluminum metal The global demand for aluminum has driven the growth of the bauxite industry, with major bauxiteproducing countries including Australia, Guinea, Brazil, and ChinaBauxite Properties, Formation, Uses » geologyscience2020年12月20日 XXV Conference «Aluminium of Siberia», Krasnoyarsk, Russia, 16 – 20 September, 2019 179 AA05 Effect of Bauxite Mineralogy on Bayer Digestion Process Selection Zhang Zhengyong Deputy Director of Science and Technology Management Department Shenyang Aluminium and Magnesium Engineering and Research Institute, (SAMI) Shenyang AA05 Effect of Bauxite Mineralogy on Bayer Digestion 2014年5月8日 The bauxite ore, Bayer process materials before precipitation, mud residue, and sand residue are therefore of radiological interest, whereas the alumina product is not8 Positional and personal monitoring data from bauxite mines and alumina refineries in Western Australia have been used to assess the abovebackground annual doses for the Bauxite Mining and Alumina Refining PMC National

.jpg)

Alumina Refining 101 The Aluminum Association

The Bayer process: How alumina is produced from bauxite The Bayer process is carried out in four steps First, after the bauxite is crushed, washed and dried, it is dissolved with caustic soda at high temperatures After this process, alumina (aluminum oxide) emerges as a fine white powder It looks much like sugar used in baking, but is The control of alumina quality is discussed in detail including the effects that alumina quality have on the aluminum smelter process with respect to environmental performance, current efficiency, and metal purity Physical Bauxite Processing: Crushing and Grinding of Bauxite Michael Wanyo, Anthony T Filidore, Benny E Raahauge; Pages 133 Smelter Grade Alumina from Bauxite: History, Best Practices 2024年1月17日 Once the bauxite ore is extracted, it undergoes the Bayer process, named after its inventor Karl Josef Bayer The Bayer process involves several stages: a Crushing and Grinding: The bauxite ore is crushed and How to Extract Aluminum from Bauxite Ore?2024年10月26日 Bauxite beneficiation is the process of using the properties of aluminum itself and using many kinds of beneficiation equipment to separate useful aluminum compounds from the associated gangue and enrich the The basic process of bauxite beneficiation LZZG

The Transformation of Bauxite to Aluminum (and

6 天之前 Bauxite Aluminum starts out as bauxite ore – an aluminum ore formed from laterite soil Bauxite is the world’s primary source of aluminum Before it can become aluminum, however, bauxite destined for use as aluminum must first 3 Digestion and Bayer Process: After grinding, the bauxite powder is mixed with a hot, concentrated solution of sodium hydroxide (NaOH) in a process called digestion This step is part of the Bayer process, which extracts alumina (aluminum oxide) from the bauxite ore The sodium hydroxide dissolves the alumina from the bauxite, leaving behind impurities such as iron What Is Bauxite Powder? Clirik Grinding MillBauxite beneficiation crushing commonly used threestage oneclosed circuit crushing process;Grinding and Classification: Grinding often adopts grid type ball mill with closed circuit by hydrocyclone Several application of bauxite 1 Crushing, sceening, calcination and make high aluminum material, which is used in refractory materials Bauxite Beneficiation by flotation method – ZJH mineralsApproximately 165 million tonnes of bauxite are mined each year Bauxite is generally transported to reÞneries by conveyor, rail, or ship Some alumina reÞneries are located close to their bauxite mines Bauxite mines typically employ 500 to 1000 people PROCESS DESCRIPTION: ALUMINA REFINING The bauxite ore contains aluminum trihydrate (Al(OH Bauxite Mining and Alumina ReÞning JSTOR

.jpg)

Bauxite mining and alumina refining: process description and

2014年5月1日 Bauxite mining and alumina refining: process description and occupational health risks Wet grinding of the bauxite ore in rod mills, ball mills, or semiautogenous grinding mills to produce fine slurry There has been a case report of mild pulmonary fibrosis—occurring in a man exposed to bauxite crushing and transport from 1936 to 2019年2月27日 The bauxite is then transported to the crushing and washing area, reducing the particle size and increasing the available surface area for the digestion stage The material that is discharged from the mill is called slurry; Continuous casting is the process whereby molten metal is solidified into a "semifinished" billet, bloom, or slab The Process of Mining Bauxite Dajcor2008年1月1日 At ITA, a number of research projects have been carried out in the past few years to develop production and processing technologies for not only commercially available but also experimental Mineral Processing technologies in the Bauxite and Alumina 2024年3月5日 Aluminum manufacture is accomplished in two phases: the Bayer process of refining the bauxite ore to obtain aluminum oxide, and the HallHeroult process of smelting the aluminum oxide to release pure aluminum Crushing and Grinding : Bauxite is the mineral form of aluminium It is the most abundant mineral in the earth’s crustHow Aluminum is Produced Metallurgy for Dummies

Bauxite crushing classification machine, process

4 天之前 Crushing equipment: jaw crusher or hammer crusher to crush large particles of bauxiteGrinding equipment: Generally, bauxite Raymond milling can be used to meet the needs of bauxite powder particle size, and the powder is 2024年2月23日 The Bauxite Mining and Alumina Refining Process Free download as PDF File (pdf), Text File (txt) or read online for free Bauxite mining involves removing shallow deposits of aluminiumrich laterite using opencut The Bauxite Mining and Alumina Refining 2023年5月15日 It is mainly used for aluminum smelting and refractory materials The bauxite calcination process is a complex process in which raw bauxite is calcined at high temperature (12001700°C) and called clinker Raw Bauxite Rotary Kiln Calcination Process and 2015年9月10日 11241 Process Description16 Metallic mineral processing typically involves the mining of ore from either open pit or underground mines; the crushing and grinding of ore; the separation of valuable minerals from matrix rock through various concentration steps; and at some operations, the drying, calcining, or pelletizing1124 Metallic Minerals Processing US EPA

Bauxite enrichment process (Bayer process): Bauxite

Bauxite enrichment process (Bayer process): Bauxite is the main carrier ore of aluminum, which is used in several sectors of industry (aeronautics, crushing, drying and fine grinding (dry In an alumina refinery bauxite is processed into pure aluminium oxide (alumina, or Al 2 O 3), which is the main raw material required for production of primary aluminium The Bayer process extracts alumina by caustic digestion of crushed bauxite at high temperature and pressure in an autoclave, followed by clarification, precipitation, washing Bayer Process an overview ScienceDirect Topics2009年8月1日 The Bayer process is the principal method for the production of alumina from bauxite worldwide The modern version of the process (developed in the 1880's) still maintains the key steps of dissolution of aluminarich minerals into hot caustic solution, separation of the insoluble phases, followed by gibbsite precipitation and calcination of the gibbsite to alumina The processing of high silica bauxites — Review of existing 2018年3月27日 Bauxite is the main source for alumina production With the rapid development of iron and steel industry and aluminum industry, highquality iron ore and bauxite resources become increasingly tense However, a lot of ironrich bauxite and Bayer red mud resources have not been timely and effectively recycled, resulting in serious problems of environmental Aluminum Mineral Processing and Metallurgy: IronRich Bauxite

.jpg)

How does HGM micro powder grinding mill process bauxite?

2024年4月2日 The extraction of aluminum from bauxite involves several stages, beginning with mining and processing the ore to separate the aluminumbearing minerals from the impuritiesThis is typically achieved through a combination of physical and chemical processes, including crushing, grinding, and digestion with sodium hydroxideThe resulting slurry is then purified The Bayer process is a chemical process for refining aluminium hydroxide, Al(OH) 3 from bauxite; this aluminium hydroxide is subsequently calcined to produce alumina, Al 2 O 3The basis of the Bayer process is an understanding of the characteristics of the sodiumhydroxide—sodiumaluminate solution relationship, namely its ability to keep sodiumaluminate in a dissolved state Chemical Processing of Bauxite: Alumina and Silica Minerals