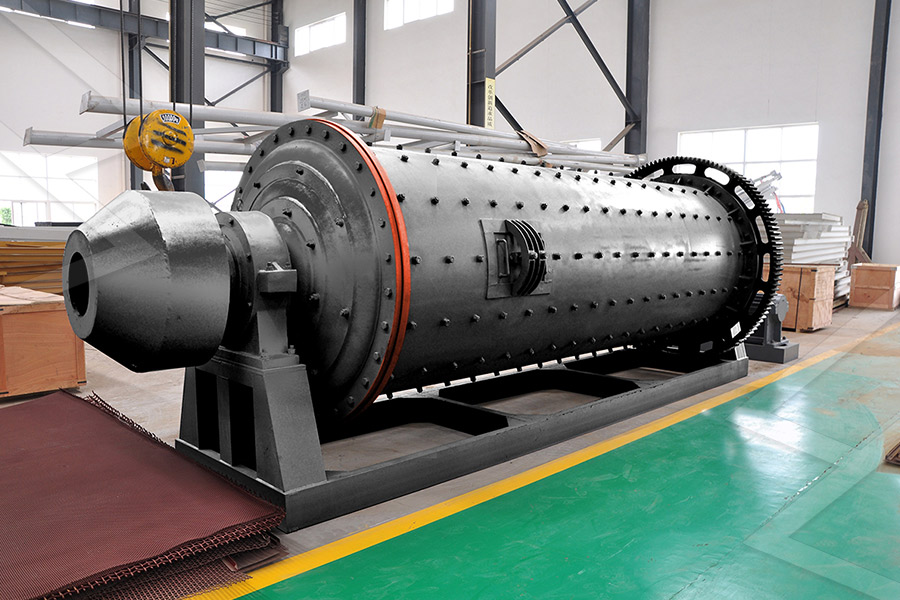

Cement Ball Mill Head Repair

BALL MILLS Ball mill optimisation Holzinger Consulting

2021年3月12日 Ball mill optimisation As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide This case study explains ball mill head extended crack repair, done by the welding process with LoTherme range of products which was designed by DH Secheron Click hereCase Study on Ball Mill Head Extended Crack 2019年11月25日 In the process of using ball mill, it is necessary to replace worn parts in time to avoid reducing the efficiency of ball mill or bringing damages to the other parts In addition to the routinely minor repair and maintenance, in Cement Ball Mill Maintenance INFINITY FOR 2021年3月11日 FLSmidth has installed almost 4000 ball mills at locations worldwide – which has given us a unique insight into the stresses and strains arising out of ball mill operations The Ball mill trunnion replacement FLSmidth

ME068: Ball Mill Operations and Maintenance cmc

2024年9月23日 maintenance of the ball mill cement grinding system The training course focuses on the latest best practices for the operation and maintenance of ball mill systems to 6 天之前 The Ball Mill Maintenance course is designed to engage in the effective use of handson learning methodology as a unique combination of theory and practical work section applied BALL MILL MAINTENANCE The Cement Institute2021年7月14日 Cement Machinery – Cement Plant the development of a crack in the trunnion casing of a Ball Mill to the head Mill ends The mill ends, or trunnion » Free case study of cement plant ball mill trunnion head crack repair 2016年10月20日 Depending upon available handling facilities, the head or shell can be lined separately in a repair bay, or after assembly of the mill proper in the trunnion bearings In the case of ball mills, all internal wearing parts will pass Ball Mill Maintenance Installation Procedure

The Cement Plant Operations Handbook International

2019年4月30日 The Cement Plant Operations Handbook is a concise, practical guide to cement manufacturing and is the standard reference used by plant operations personnel worldwide 2021年3月11日 %PDF14 %âãÏÓ 155 0 obj > endobj xref 155 48 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n Ball mill trunnion replacement FLSmidth2024年10月11日 Cement Ball Mill Bearing Bushing Ball Mill Liner Large girth gear Ball Mill Head Rotary Kiln Tyre Ball Mill Trunnion Metallurgical Rolling Mill Chocks Slag pot Slag ladle Ball Mill Head Chat online Order Online Email +86 Product advantages Production process View more products Get a Quote Brochure Product advantagesBall Mill Head TenfayeAn inefficient ball mill is a major expense and could even cost you product quality The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance In our Ball mill for cement grinding FLSmidth Cement

Cement Ball Mill Maintenance INFINITY FOR CEMENT EQUIPMENT

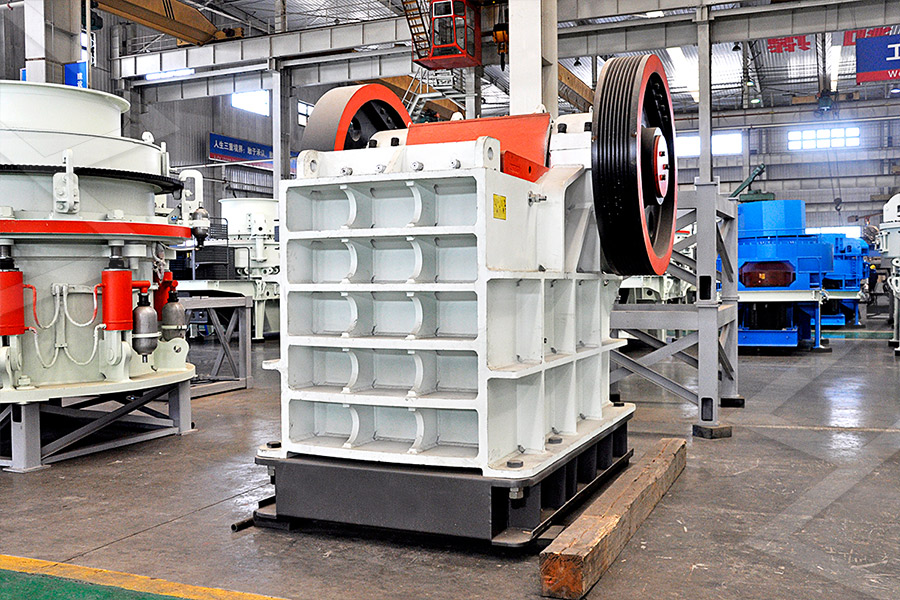

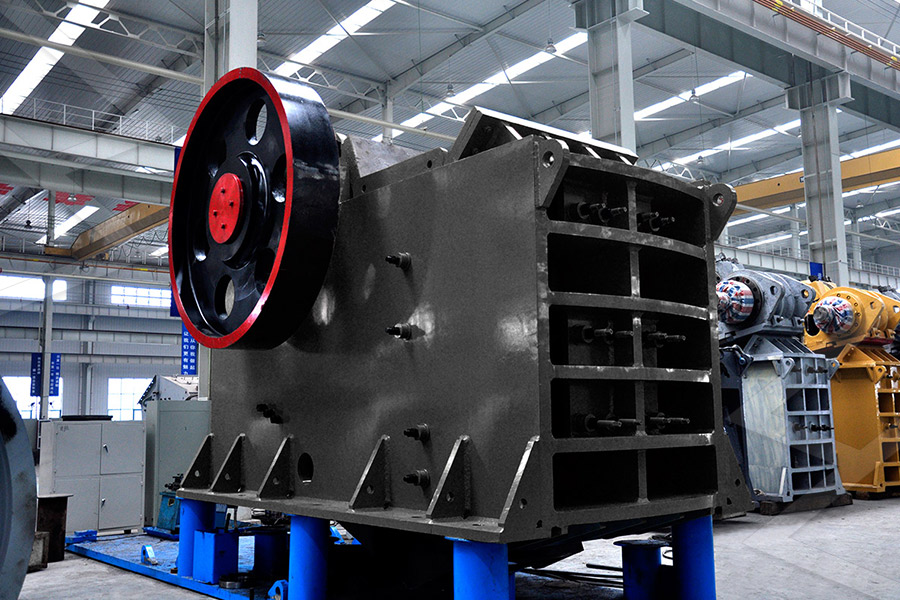

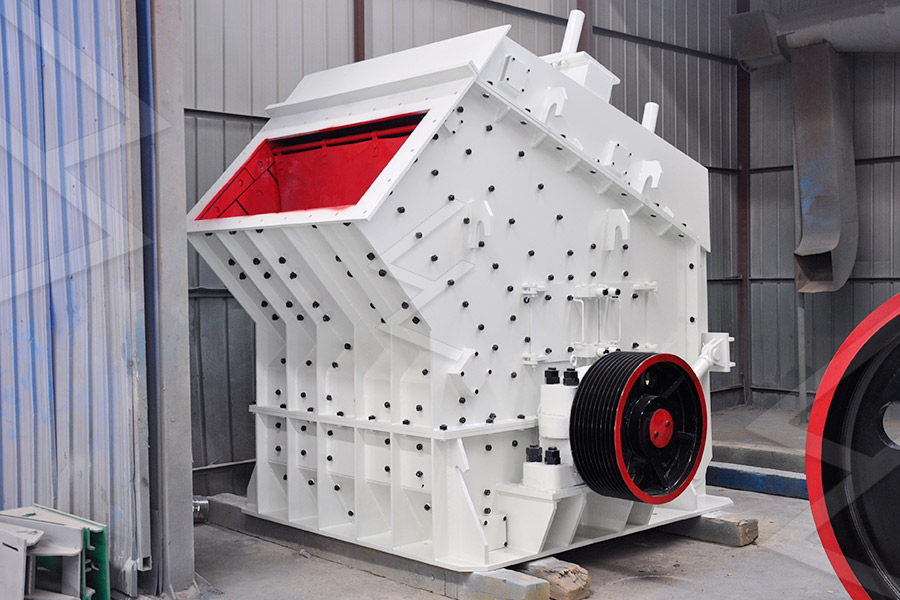

BALL MILL INSPECTION PROCEDURE source : thecementgrindingoffice Introduction This document is intended to help the staff of the cement plants On a process point of view, a mill inspection is only representative if the grinding mill circuit is in a steady working condition with a representative cement product2024年8月5日 The comprehensive production process of the mill head inlet and discharge for ball and SAG mills, meticulously designed and manufactured by ABS used to evaluate and optimize the design of complex mechanical components In the context of a Mill Head for a cement mill, this analysis allows us to determine how the structure will respond under Mill head manufacturing process for ball and SAG mills2013年2月26日 The other major repairs that take place on ball mills are to replace the liners and diaphragms and on a VRM to replace (or turn) the rollers and replace the table The liners on a ball mill generally last up to 5 years in the first chamber and as long as 8 years in the second chamber and therefore are infrequently paring ball mills and VRMS for cement grindingDiscover wide range of highquality ball mill spare parts for cement plant AGICO Cement specializes in providing cement plant spare parts such as girth gears, shells, heads (endups), liner plates, trunnions, and grinding media for ball mills Enhance the performance and longevity of your ball mill with our reliable spare parts Choose from our extensive selection and ensure Ball Mill Spare Parts AGICO Cement Plant

17 Signs of Problems with Ball Mills: Quickly Remove Hidden Troubles

2023年2月15日 High temperature of the ball mill will affact the efficiency 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% 10% 4 when the moisture is greater than 5%, the ball mill will be unable to perform the grinding operation 5 The bearing of the ball mill is overheated and the motor is overloaded ReasonsCement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plantsThe function of the separator is to separate the finesized particles from the coarsesized particles, so as to avoid material condensation and over grinding in the mill, and improve the milling system’s grinding efficiencyCement Milll Separator Cyclone Air Separator in Cement PlantThe grate has openings that allow the ground material to pass through while retaining the grinding media inside the mill How to Repair Ball Mill Inside Parts Repairing ball mill inside parts can be a challenging task, but it is essential to ensure the optimal functioning of the mill Here are some steps to repair the inside parts of a ball mill:What are the Components of Ball Mill Inside and How to Repair Its weight, volume, and cost occupy a large proportion of the whole set of ball mill equipment, and its work efficiency has an important impact on the normal operation of the ball mill Ball mill pinion is also called ball mill pinion gear Ball Mill Pinion Gear cement grinding plant s

Ball Mill In Cement Plant Cement Ball Mill

Of course, even if we set a more appropriate cement fineness, it is difficult to change the current situation that the flow velocity in the opencircuit ball mill is only 1/21/3 of that in the closedcircuit ball mill with the same specification, Cement mills are the milling machines used in cement plants to grind hard clinker into fine cement powders Cement ball mill and vertical roller mill are two most widely used cement mills in today’s cement grinding plants and are also the Cement Mill for Sale Buy Cement Ball Mill2020年6月14日 It is a component in the cement making process Today’s Ball Mills are typically designed with a slide shoe bearing These bearings have replaced the more traditional trunnion bearings, as they are less expensive to purchase and maintain The function of the slide shoe bearing is to keep the mill aligned to the mechanical process while Improving Mill Shoe Bearing Reliability and ProductivityBespoke Solutions Save You Money When we tackled the in situ recovery of a 915mm diameter x 915 mm long cement mill bearing journal, our orbital machining technology salvaged the shaft diameter at a fraction of the cost of conventional shaft replacementIngenuity and innovation underpin our position as a leader in specialist engineering services for the process industriesMining, Mineral, Cement, and Aggregates Repair Work

.jpg)

Failure analysis of a ball mill located in a cement’s

2022年8月1日 The ball mill understudy has a length of 1307 m in its cylindrical geometry and a length between supports of 162 m (Fig 1 a,b)The formation of cracks in the middle span has been identified, generally spreading from the holes near the maintenance manhole, as shown in Fig 1 c Certified welders carry the repairing procedure using PERMA 622 electrodes [1]The proven classical option for cement grinding Whether employed as a twocompartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding Used in combination with the sepol® highefficiency separator, ball mills can reliably Ball Mill thyssenkrupp Polysius2015年7月28日 Ball Mill TRUNNION BEARINGS Swivel type leadbronze bushed trunnion bearings are generally furnished on large diameter ball Mills The bearing swivels are of Meehanite metal spherically turned outside and bored and faced inside to receive the removable bushing The bushing is bored and scraped to fit the mill trunnionTrunnion Bearing Assembly Ball Mill Rod MillFine Grinding and Mill Cooling PROBLEM Insufficient mill cooling lead to material agglomeration on balls and liners The grinding is not any more done by balls against material but by material against material SOLUTION Adapted mill cooling, playing with:Clinker temperatureMill ventilationWater injectionEVERY COMPONENT OF BALL MILL DETAILED EXPLAINED INFINITY FOR CEMENT

.jpg)

Ball charge optimization INFINITY FOR CEMENT EQUIPMENT

Previous Post Next Post Contents1 Ball charge optimization2 1 How to use the BP21 2 Description of the main indicators used in this BP2101 The residue on 2mm/4mm before partition wall2102 Material filling level and ball charge expansion211 Cement mill specific power 1st compartment 212 Raw mill specific power 1st compartment Ball charge During the grinding process of cement ball mill, the cement particle size distribution determines the setting time, stability, strength grade and other characteristics of cement The accurate measurement of cement particle size distribution is of great significance to the control of cement quality Once the traditional soft sensing model of cement ball mill particle size is established, Soft Measurement Modeling of Cement Ball Mill Particle Size Buy ball mill end cover for ball mill production Casting ball mill head with ISO, CE certification Ball mill end cover with trunnion for sale Click for details now!Ball Mill End Cover and Ball Mill Head for SaleUpgrading an existing ball mill circuit with hydraulic roller presses and TRIBOMAX® wear surfaces achieved a 127% increase in production, at the same time as lowering power consumption by 25%, at JK Cement’s Mangrol cement Ball mill upgrade cuts energy consumption by

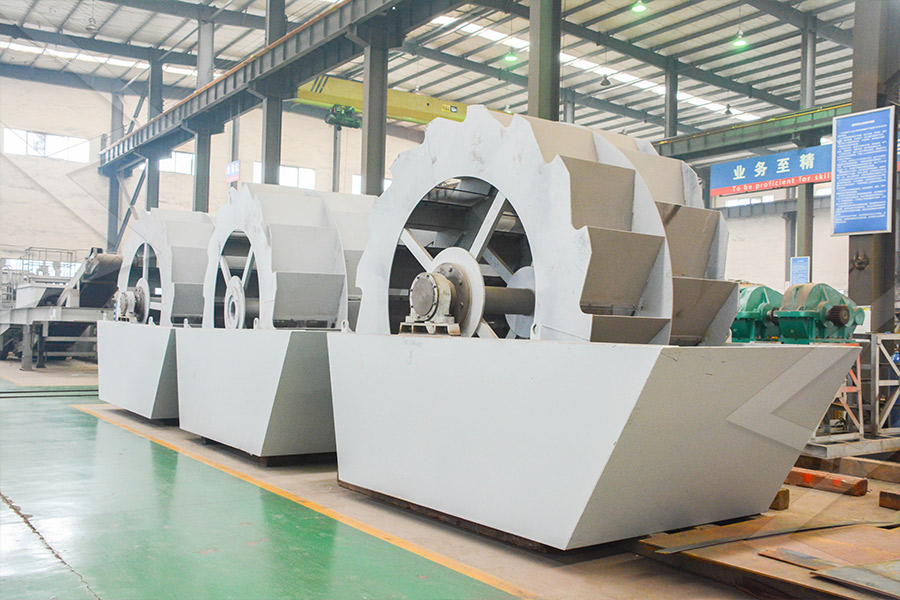

Cement Bucket Elevator Cement Eleavor Chain Type Belt

Cement bucket elevator components The vertical bucket elevator is mainly composed of a hopper, a traction belt (or chain), a driving device casing, and an inlet and a discharge port The hopper holds the material There are mainly three types of hoppers according to the nature of the conveyed material and the structural characteristics of the elevator, namely the deep hopper Maintaining a cement ball mill is crucial for ensuring optimal performance and longevity of the equipment Regular maintenance helps prevent costly breakdowns and ensures smooth operation This practical guide provides detailed steps, tools required, manpower needed, and recommended schedules for maintaining a cement ball millStepbyStep Guide to Cement Ball Mill MaintenanceAGICO Cement produces large size casting steel ball mill trunnion according to customer’s drawings and requipments We have advanced casting, machining, and testing equipment, and sets up a strict quality management system to control every step of the manufacturing process and ensure the top quality of ball mill trunnionBall Mill Trunnion AGICO Cement PlantAccording to different grinding systems, the oftenused cement mills include ball mill, roller press, and vertical roller mill In addition to the cement mill, other commonly used equipments in the cement grinding station include cement mill separators , bag filters and ESPs , cement silos , conveyors , bucket elevators, cement roto packers , etcCement Grinding Plant Expert Cement Grinding AGICO Cement

Computation of charging media for a double compartment cement ball mill

2024年1月26日 Grinding media is mostly prepared from high chrome steel Ball mills are efficiently utilized for final grinding of clinker It grounds the raw mix (clinker) into fine powder Ball mills are available of different sizes and capacities Ball mill may be of two compartment or three compartments The schematic view of cement ball mill is shown in 2021年4月27日 Operation and Elements of a ClosedCircuit Ball Mill System Cement ball mills typically have two grinding chambers The first chamber is filled with larger diameter grinding media andlined with lifting liners The first chamber coarsegrinds the feed material and prepares it for the second chamber The second chamber is the fine grinding OPTIMIZATION OF CEMENT GRINDING OPERATION IN 2022年3月16日 Cement ball mill is a kind of equipment for further fine grinding of materials, with high fineness It is widely used in industry, metallurgy, chemical industry, cement and other industries The What is a Cement Ball Mill? How to Use It? by cicemechBall mill girth gear Rotary kiln thrust roller Ball mill trunnion Rotary kiln pinion Ball mill head Rotary kiln roller shaft Ball mill bearing bush Rotary kiln bearing housing Ball mill bearing housing ManufacturerFactory Rotary kiln spring plate ManufacturerFactory Ball mill transmission connection ManufacturerFactoryBall Mill Rotary Kiln Vertical Roller Mill Manufacturer Tongli

Cement Mill Separator High Efficiency Cement

A cement mill separator is also referred to as a cement classifier because it also plays an important role in precisely controlling the grain size of finished cement products SINOMA has developed models of cement separators for meeting 2024年3月22日 85tph Cement Ball Mill In Indian Cement Plant; Ore Dressing Line; Online Visit of AGICO CEMENT Chat Online Over 15,580 Customers Realtime onsite repair, maintenance, and operation, so that Ball Mill for Sale Cement Mining and Chemical 2021年7月9日 Due to the factors of production site and working conditions, the consumption and loss of the ball mill itself (ball mill, steel ball, liner) can not be ignored In order to have a long service life and good efficiency of the ball mill, the daily maintenance and repair of the cement ball mill is very importantHow to maintain cement ball mill? winnermacgroupTypes of cement mill liners: classifyingliners Classifyingliners are the best form of cement mill liners to adapt the grinding charge to the feed material´s granulometry while keeping a smooth material flow going They are efficient energy wise because of Cement mill liners Magotteaux

Cement Separator Ball Mill Optimization

Find: required maximum ball size – F80 – Maximum ball size (mm) Mill performance test Steps 1 Recording of related operational data 2 Air flow measurement 3 Crash stop and visual inspection in mill 4 Sampling in mill 5 Evaluation of test 1 Recording of related operational dataTube Mill Feed rate, Return, Grinding aids, Water Find topquality mill head casting solutions for ball mills, cement mills, rod mills, and tube mills Our precisionengineered castings ensure durability and optimal performance in various milling applications Skip links Skip to primary navigation; Skip to content; Call Us +91 Mail Us info@mahavirconcast Who are we;Mill Head Casting For Ball Mill, Cement Mills, Rod Mills, Tube MillsA cement roller press is also referred to as a roller press cement mill, or cement roller press machineIt is a grinding equipment that can be applied for greenfield cement grinding plants or upgraded cement grinding plants It has the features of low consumption and high efficiency compared to the traditional ball mill pregrinding system The output in a roller press grinding Roller Press In Cement Plant Roller Press Cement MillA ball mill maintenance procedure is a crucial process in ensuring the longevity and efficient operation of your mill A poorly maintained ball mill can cause significant downtime, leading to costly repairs and lost production In this article, we will discuss the importance of regular maintenance, premaintenance steps, the ball mill maintenance procedure, postmaintenance Ball Mill Maintenance Procedure: Tips for Maintaining Your Mill