Hpgr For Finish Cement Crusher

43.jpg)

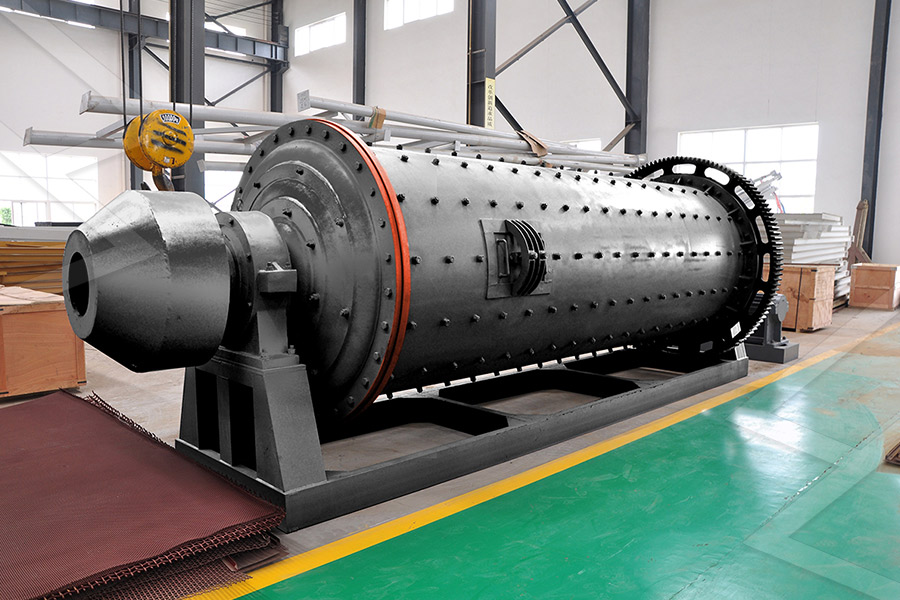

Our Dynamic HPGR Technology for Mineral

Used in mining applications for the last 30 years, HPGR technology has streamlined the transition between mineral grinding and crushing by accepting largersized particles compared to ball mills, and producing finersized 2022年3月15日 This paper unifies highpressure grinding rolls crusher (HPGR) models of the working gap, mass flow rate, power draw, and centre and edge product particle size Unifying highpressure grinding rolls models ScienceDirect2023年1月1日 HPGR utilising a particlebed crushing mechanism to generate finer products has gradually acquired a reputation in the metal mining industry (Van Drunick and Smit, 2006), for Evaluating the performance of an industrialscale high Modern polysius® grinding systems for cement applications are often designed as combi grinding systems consisting of a polycom® HPGR, a staticdynamic sepol® separator, and a ball mill This design enables an optimal interaction of polycom® HPGR cuttingedge technology in

First choice for HPGR technology and service Kivigrupp

2016年5月4日 filtering of the ground ore In these cases, HPGR grinding can provide a feasible alternative One of the most important subjects in HPGR grinding is the wear of the roll 2019年8月7日 Despite having a significantly smaller footprint than conventional “tumbling” mills, HPGR’s are highcapacity crushing units delivering a high degree of size reduction, resulting Why HPGRs are revolutionising mill circuits Weir Weir Group2024年10月15日 Our high pressure grinding rolls can be equipped with finish grinding system, cement combined grinding system, semifinish grinding system, and more processing systems Our core database and process simulation High Pressure Grinding Roll Grinding Mill 2022年10月6日 across the full width of the tyre Enduron® HPGRs are unique, the only machines with the capability to reliably deliver eficient roller skewing, necessary in real world Enduron High Pressure Grinding Rolls Weir Group

Dry finish grinding with HPGRs: The next step ahead in

2014年1月1日 Historically, HPGRs have been used mainly as tertiary crushers in mineral applications for the production of ball mill feed In the cement industry, however, HPGR 2006年2月1日 Semantic Scholar extracted view of "High pressure grinding rolls (HPGR) applications in the cement industry" by N Aydogan et al Skip to search form Skip to main content Skip to account menu Semantic Scholar's Logo An Improved HighPressure Roll Crusher Model for Tungsten and Tantalum Ores H Anticoi E Guasch +10 authors J J FelipeHigh pressure grinding rolls (HPGR) applications in the cement Our HPGR Rolls utilizes the principle of high pressure inter particle comminution to grind various types of ore, industrial minerals, or clinker for cement production Using our proprietary edge, stud and roll design and unique state oftheart HighPressure Grinding Rolls Cast Steel ProductsHPGR in Finish Grinding Circuit Our solution is to crush the pebbles with a cone crusher and then feed them to an HPGR This arrangement will crush the pebbles enough that that you can feed the product directly into the ball mill sump FLSmidth is a full flowsheet technology and service supplier to the global mining and cement High Pressure Grinding Roll for advanced crushing FLSmidth

.jpg)

High pressure grinding rolls HPGR for iron ore, cement

4 天之前 High pressure grinding rolls or HPGR is such a kind of equipment that uses this principle for crushing operations HPGR has been widely used in fine crushing of metal ore beneficiation plants, crushing in cement industry, granulation in chemical industry and fine grinding of pellets to increase specific surface areaThe cement roller press, also known as roller press in cement plant, high pressure grinding roll (HPGR), is a kind of cement equipment for brittle materials, apply for grinding cement clinker, cement raw material, gypsum, coal, quartz sand, iron ore, blast furnace slag, and other materials The cement roller press is generally applied to the cement grinding plant, according to the real Cement Roller Press, Roller Press In Cement Plant HPGR Crusher2023年11月29日 HPGR is the most efficient comminution product in grinding and milling High and rising energy prices can make a real dent in your profitability Bring down energy consumption and increase your overall efficiency with the HPGR Pro, our latest generation high pressure grinding roll HPGR Expertise 35+ years of experience supplying HPGR’s HPGR / HPGR Pro The next level in grinding FLSmidth2006年2月1日 1 Introduction Schönert (1979) has shown that the most energy efficient method of comminuting particles is to compress them between the two plates Compressing a particle bed between two counter rotating rolls was achieved by the invention of the high pressure grinding rolls (HPGR) (Schönert and Knobloch, 1984)The first commercial application of HPGR was in High pressure grinding rolls (HPGR) applications in the cement industry

.jpg)

High Pressure Grinding Roll Grinding Mill Supplier CITIC HIC

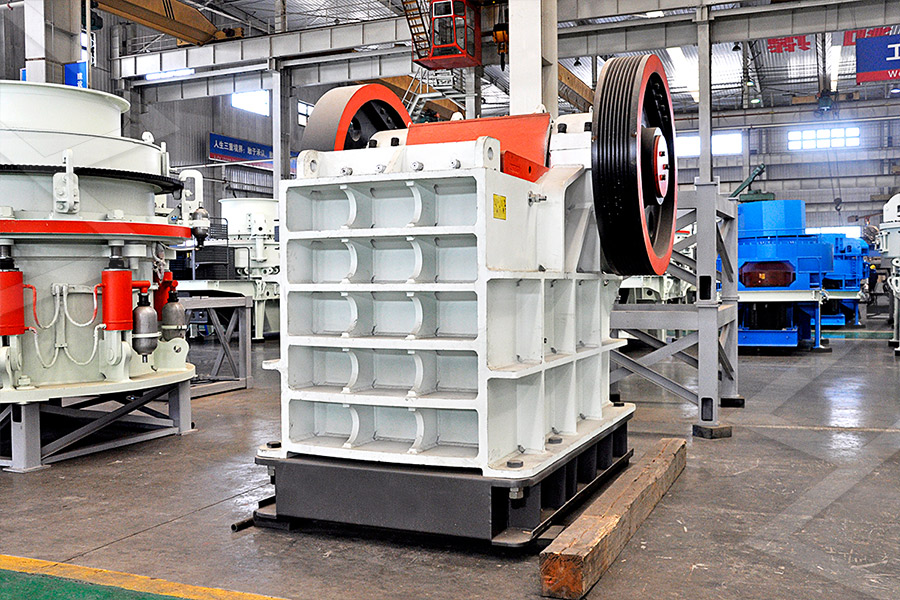

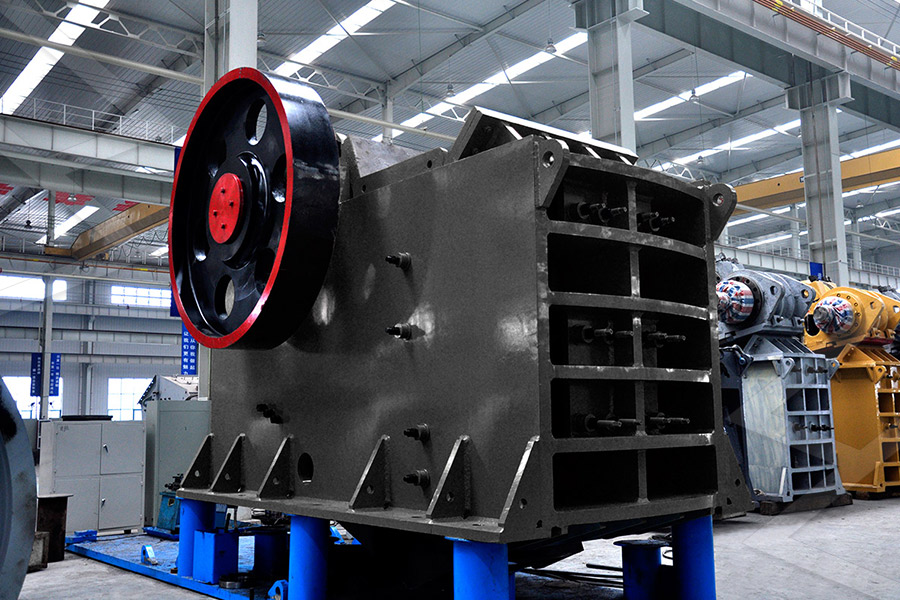

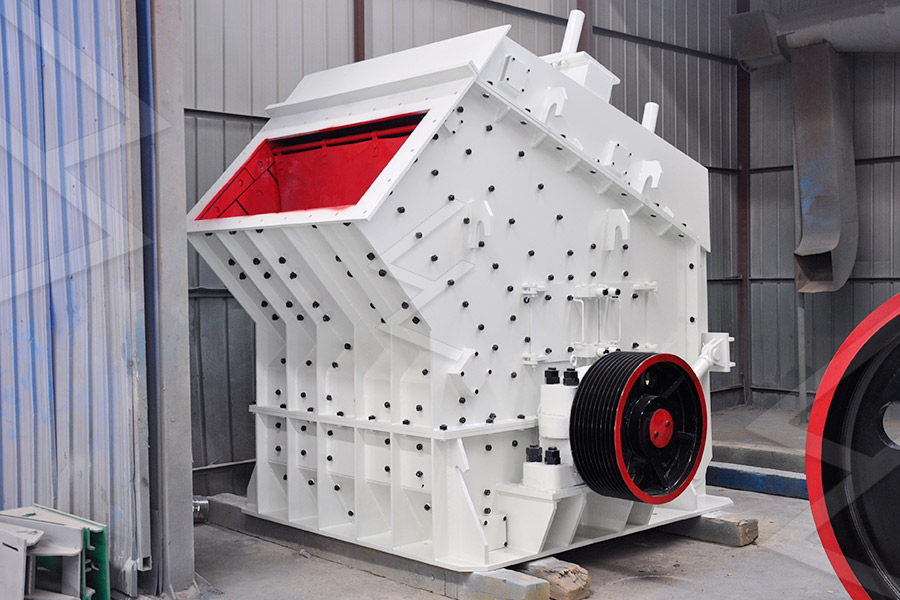

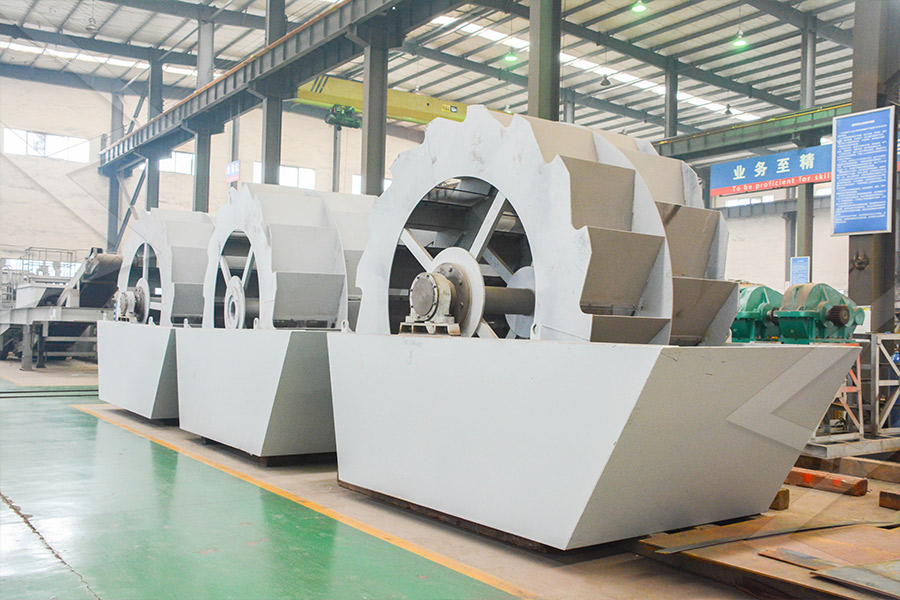

2024年10月15日 Our high pressure grinding rolls can be equipped with finish grinding system, cement combined grinding system, semifinish grinding system, and more processing systems Our core database and process simulation software can Enduron® high pressure grinding rolls (HPGR) set the benchmark for energy efficient grinding by using dynamic skewing to provide bestinclass wear life for mining applicationsEnduron® High Pressure Grinding Rolls (HPGR) Weir Weir 2010年8月1日 For a given feed size distribution, an HPGR in open circuit will generate a finer product than a conventional (cone) crusher, depending on gap setting of the conventional crusher Even if a comparable 80% passing size would result, the proportion of fines is significantly higher in the HPGR product than in for instance a cone crusher product Flowsheet considerations for optimal use of high pressure 2019年10月30日 The cement crusher is necessary in the cement production line, how to choose a suitable crusher? AGICO Cement is a cement equipment manufacturer, we supplies jaw crusher, cone crusher, impact crusher, How To Choose Cement Crusher? Jaw Crusher,

.jpg)

EnergyEfficient Technologies in Cement

2016年10月5日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in 2023年6月19日 HRC crusher automation HRC 8 and HRC 800 are available with Metso crusher automation which controls and monitors crusher and ancillary equipment helping to achieve the best performance and protection to the machine maximizing uptime and safety Crusher automation is provided as a complete package, including fully automated hydraulicHigh pressure grinding rolls HRC™ 8 HRC™ 800 Metso1997年1月1日 Parallel to the HPGR application, important improvements have also been made to the technology (ALSMANN, 1996, FARAHMAND EHRENTRAUT, 1997, LIM AND WELLER, 1999 and even in the machine (PDF) Modelling of the HPGR crusher ResearchGate2016年1月10日 HPGR is never more than 25–35 kWh/t even in grinding the hardest ores Nevertheless advantages and shortcomings of HPGR should be compared with SAG mills in each individual case Energy consumed in medium crushing, HPGR grinding and ball milling can be 40% lower as against SAG milling,HIGH PRESSURE GRINDING ROLLS—A PROMISING AND

Finite element analysis of highpressure grinding rolls for

2022年1月1日 Initial surface imperfections which serve as sites for crack nucleation can be controlled by giving a better surface finish to the Levent Ergu¨n, , “High Pressure Grinding Rolls (HPGR) applications in the cement industry”, Miner And Jose Juan De Felipe, “An improved highpressure roll crusher model for tungsten and tantalum ores Product Name: High Pressure Grinding Roll / HPGR Application: limestone, clinker, mineral ores crushing / pregrinding Capacity: 100 ~ 1450 T/PAGICO High Pressure Grinding Roll (HPGR) AGICO Cement 2024年10月1日 Based on the above methods, a typical order of the comminution circuit can be proposed for the given type of material (Figure 5): crusher (usually jaw crusher) > HPGR (with or without recycle) > ball mill (Giblett and Morrell Citation 2016; Liang et al Citation 2016; Morrell Citation 2010; NapierMunn et al Citation 1996)Full article: Review of HighPressure Technology in Terms of AGICO CLM Series high pressure grinding rolls (HPGR) are efficient and energysaving crushing equipment that can be widely used in crushing and grinding operations in cement, chemical, mining, metallurgy, and other industriesAGICO High Pressure Grinding Roll (HPGR) AGICO Cement

High Pressure Grinding Rolls for Minerals AusIMM

2021年6月24日 ThyssenKrupp Polysius I:\Daten\McGill\McGill presentation rev 1doc 1 / 20 Adresse: ThyssenKrupp Polysius AG, GrafGalenStraße 17, 59269 BeckumNeubeckum Telefon: 02525 990 Telefax: 02525 992100 EMail: polysius@thyssenkrupp Internet: polysius Vorsitzender des Aufsichtsrats: Dr Niclas Müller Vorstand: DrIng Detlev 2010年8月1日 For a given feed size distribution, an HPGR in open circuit will generate a finer product than a conventional (cone) crusher, depending on gap setting of the conventional crusher Even if a comparable 80% passing size would result, the proportion of fines is significantly higher in the HPGR product than in for instance a cone crusher product Flowsheet considerations for optimal use of high pressure grinding 2022年11月23日 Contrary to popular belief, HPGR technology is not new, with first applications in the mid1980s (Morley, 2010) While most applications can be found in cement, the applications in mining are increasing Today, there are many successful applications in base metals, precious metals, and indGustrial minerals proving the reliability andHPGR: WHY SKEWING IS A REQUIREMENT FOR Simply put, the roller press is the most energyefficient grinding machine on the market Since its commercial introduction into the cement industry by KHD in the 1980s, hundreds of them have been installed in the cement and minerals Roller Press KHD Humboldt Wedag

.jpg)

Potential of HighPressure Grinding Roll (HPGR) for Size

2022年3月16日 Abstract HPGR has been found to be efficient size reduction equipment compared to conventional size reduction equipments due to its potential processing benefits in terms of energy savings, improved exposure or liberation and particle weakening The objective of the current work is to study the optimization of different process parameters during grinding 2022年3月15日 This paper unifies highpressure grinding rolls crusher (HPGR) models of the working gap, mass flow rate, power draw, and centre and edge product particle size distribution models to produce a framework that allows the simulation of the equipment for process optimization and control studies Calculating the model parameters requires exclusively Unifying highpressure grinding rolls models ScienceDirect2020年7月28日 CRITICAL HPGR PARAMETERS HPGR roll diameters typically range from 05 m to 28 m, depending on the supplies, and roll widths vary from 02 m to 18 m The aspect ratio of the rolls also varies as a function of manufacturer Typical HPGR throughput rates range from 20 to 3,000 tph, with installed motor power as high as 3,000 kW per rollHigh Pressure Grinding Rolls 911MetallurgistThe HPGR (high pressure grinding rolls/rollers) is the core equipment of the high pressure grinding process The machine reduces particles by compressing and crushing the feed between two counter rotating, parallel rollers with a small gap between them This forces the rocks against each other and compresses the feed’s density to 80% of its solid [](HPGR) high pressure grinding rolls/rollers for cement, ores

.jpg)

Quantification of HPGR energy efficiency effects on

2022年8月24日 cement industry by then (Schönert, 1988) Since then, a worldwide trend towards HPGR application has been established (Klymowsky, 2002), first in the cement industry but soon after different ways, merely by compression in the jaw crusher and the HPGR or by blow and shear in the hammer mill 9 of 13 Lecture on IMPC AsiaPacific 2022, August 2013年9月1日 The first application of the HPGR was in 1985 in a cement plant, mainly for capacity improvement purpose In some applications it appears as a pebble crusher in AG milling HPGR has attracted the attention of many researchers for around two decades, resulting in various modeling approaches for throughput or size reduction of the equipment Application of population balance model to HPGR crushing2022年10月6日 From a laboratory jaw crusher From a HPGR, showing myriad microcracks Compared to other crushers HPGR Crushing, 50 N/mm2 HPGR Crushing, 35 N/mm2 Conventional Crushing The high pressure force in the material bed promotes differential stresses locally within the ore grains and between the ore minerals and the surrounding waste rockEnduron High Pressure Grinding Rolls Weir Group2006年2月1日 The crushing devices were mainly concluded of jaw crusher, cone crusher, roll crusher, high pressure grinding rolls (HPGR) (Ergu and Benzer, 2006; Ghorbani et al, 2013) Due to the large spans of High pressure grinding rolls (HPGR) applications in the cement industry

.jpg)

Cemented carbide studs for HPGR for Mining

Tungsen carbide studs for HPGR, wearresisting parts for mining and metallurgical highpressure grinding roll crusher Tungsten carbide studs are widely used in HPGR crusher in minerals and metallurgy industry Union Going forward FLSmidth will not only be well positioned to supply the HPGR Pro, but also to service these machines, and others like it over the life of the project FLSmidth is a full flowsheet technology and service supplier to the global HPGR Pro Grinding has never been better2019年9月3日 a revolutionary HPGR crushing circuit that challenges traditional expectations +20% throughput +120 million metric ton of processed ore +60,000 hours of operation15% energy consumption Gyratory crusher Cone Crusher HRC Vertimill 10 11 Through our knowledge and experience, we work with our customers to create solutions thatHigh pressure grinding rolls HRC Metso2015年3月12日 The HPGR technology offers several options to reduce the water consumption within a plant Dry finish grinding plants In addition to eliminating water requirements for the comminution process, higher reductions in plant operating costs can be achieved in cases where the HPGRs are utilised to finish the grind in conjunction with air separatorsDevelopments in HPGR technology Mining Magazine

.jpg)

Plant and Machinery

Highpressure grinding rollers (HPGR) During the highpressure comminution process, rather than being crushed between the roller surfaces, individual grains or particles are in effect compacted to a dense flake through exposure to relatively high pressures After deagglomeration, the flake normally shows a substatial amount of completed or incipient cracking emanating from the 2024年10月25日 Used commonly in cement production since the 1980s, HPGR technology was applied to iron ore and diamond processing in the following decade, and after the turn of the century established a firm foothold in nonferrous ore operations as well, with HPGR circuit installations in large concentrators at the Cerro Verde, Boddington and Morenci mines HPGRs Grind Out Larger Role in Plant Productivity E MJ2009年12月1日 Conventionally multicompartment ball mills are used in finish grinding of cement However, they are relatively inefficient at size reduction and have high energy consumption, so it is increasingly common to find grinding technologies such as High Pressure Grinding Rolls (HPGR), vertical mills and Horomill ® in cement plants As recorded in the Horizontal roller mill (Horomill®) application versus hybrid HPGR/ball 2009年12月1日 1 IntroductionConventionally multicompartment ball mills are used in finish grinding of cement However, they are relatively inefficient at size reduction and have high energy consumption, so it is increasingly common to find grinding technologies such as High Pressure Grinding Rolls (HPGR), vertical mills and Horomill ® in cement plants As recorded in the Horizontal roller mill (Horomill®) application versus hybrid HPGR/ball

The new FSeries HPGR is a successful prospect for Ivrindi Gold

2020年10月19日 Primary crusher – TST 1900 Jaw Crusher; FLSmidthLudowici 36 x 73 m doubledeck screens (qty 3) Secondary crusher – Raptor 1300 Cone Crusher; Tertiary crusher – F3200W HPGR; In addition to the 12 months of site service mentioned above, we also provided training for site personnel